In the ever-evolving manufacturing landscape, the demand for high-performance gasket sheets is more pronounced than ever. According to a recent market report by MarketsandMarkets, the global gasket market size is expected to reach USD 10.2 billion by 2025, growing at a CAGR of 5.2% during the forecast period. This growth underscores the vital role that gasket sheets play in sealing applications across various industries, including automotive, aerospace, and oil and gas. With increasing pressure on companies to innovate and adopt more sustainable practices, global buyers are exploring innovative alternatives to traditional gasket sheets that not only meet performance standards but also align with eco-friendly initiatives. In this blog, we will delve into some of these cutting-edge alternatives and their potential to transform the sealing solutions industry.

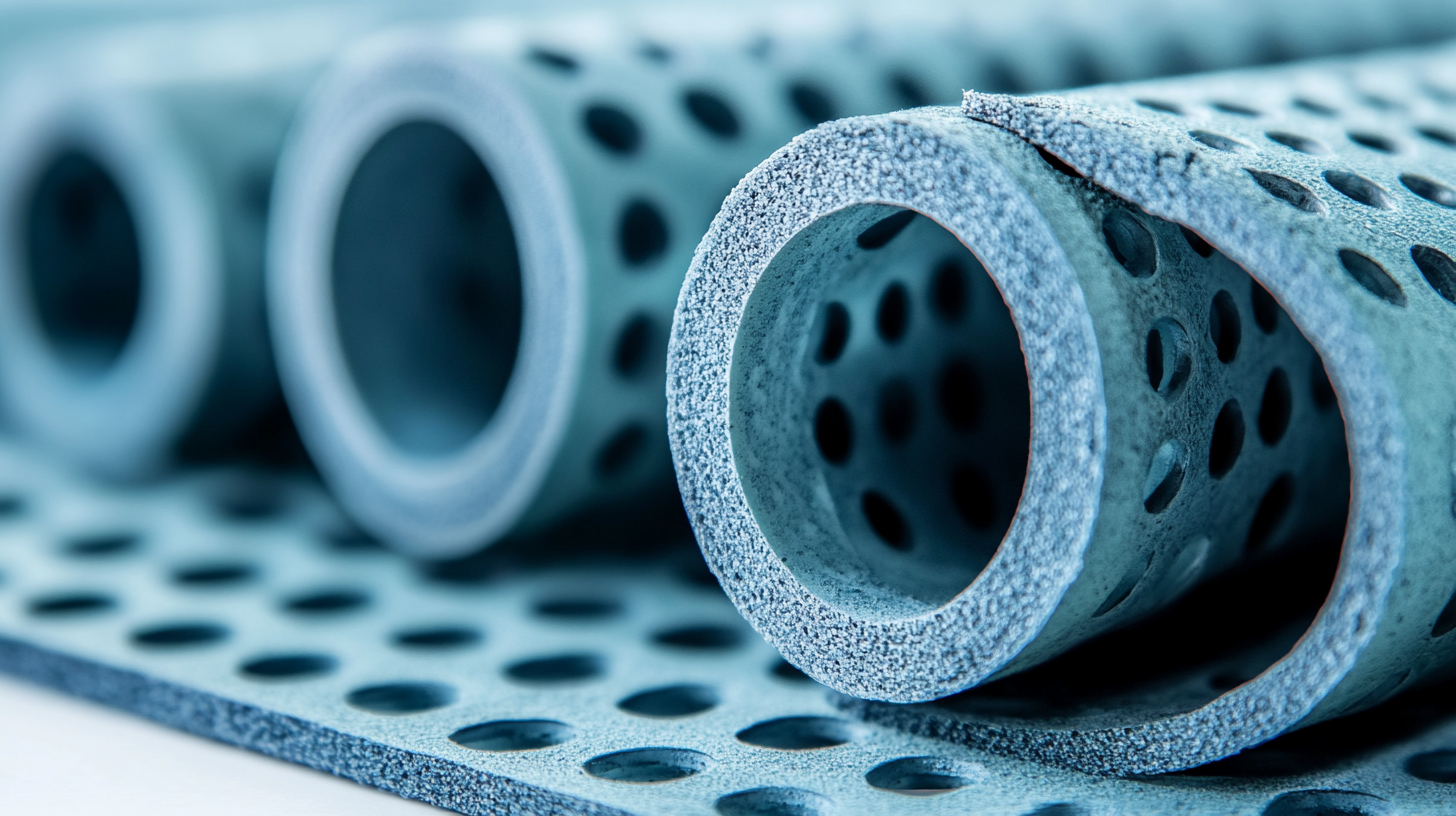

When selecting gasket sheet alternatives, global buyers should consider several key factors that can significantly impact performance and longevity. One of the most crucial elements is the material composition. Various materials such as rubber, cork, and metal composites offer unique benefits. For instance, rubber gaskets are known for their flexibility and resistance to environmental factors, while cork-based options can provide excellent sealing properties in certain applications. Understanding the specific needs of your application will help determine which material will deliver the necessary performance.

Another important factor to consider is temperature and pressure resistance. Different gasket sheet alternatives have varying thresholds for heat and pressure, which can affect their effectiveness in demanding conditions. For example, high-temperature applications may require silicone or aramid gaskets, while low-pressure environments might utilize softer materials. Evaluating the operational conditions and consulting with manufacturers regarding their product specifications is essential to ensure the chosen alternative will withstand the operational demands.

Finally, the ease of installation and maintenance should not be overlooked. Some gasket alternatives may require specialized tools or techniques for installation, while others can be applied easily. Additionally, consider the lifespan of the material; investing in a durable gasket that requires less frequent replacement can yield long-term savings and reduce downtime. By carefully weighing these factors, buyers can make informed decisions and select the most suitable gasket sheet alternatives for their needs.

When selecting gasket sheets, global buyers are increasingly looking beyond traditional materials to innovative alternatives that enhance performance, durability, and sustainability. This comparative overview highlights some of the top innovative materials that are making waves in the gasket industry. Among these, expanded graphite, polytetrafluoroethylene (PTFE), and composite materials stand out for their exceptional sealing capabilities and temperature resistance. Expanded graphite, known for its excellent chemical resistance, offers a lightweight option that maintains integrity under high pressures. PTFE is prized for its non-stick properties and can withstand extreme temperatures, making it ideal for specialized applications.

In recent years, the gasket sheet industry has seen a significant shift towards sustainability, with innovative alternatives emerging to address environmental concerns. Traditional gasket materials often rely on petroleum-based products, contributing to resource depletion and increased carbon footprints. According to a report by the Global Plastics Alliance, approximately **80% of gasket sheets are made from non-renewable resources**, making the need for eco-friendly options more pressing than ever.

One promising alternative gaining traction is the use of bio-based composite materials, which can reduce dependence on fossil fuels while maintaining high-performance characteristics. These materials often incorporate natural fibers, such as hemp or flax, combined with biodegradable polymers. A study conducted by the Eco-Innovation Observatory found that utilizing such bio-composites can diminish greenhouse gas emissions by up to **50%** compared to conventional gasket sheets. Additionally, these sustainable options often provide equivalent or superior thermal and mechanical properties, making them viable for a variety of industrial applications.

Another innovative approach involves the development of recycled rubber gasket sheets. Research indicates that sourcing raw materials from post-consumer waste not only conserves resources but also diverts significant amounts of waste from landfills. According to a report by the Rubber Manufacturers Association, using recycled rubber can reduce energy consumption during production by **40%**. This shift towards incorporating recycled materials into gasket production is a crucial step towards achieving circular economy principles in the industry.

When considering alternatives to traditional gasket sheets, it's crucial to conduct a thorough cost-effectiveness analysis. Many buyers may overlook less conventional materials that could provide significant savings without compromising performance. Options such as rubber, cork, and composite materials can be less expensive while still offering excellent sealing capabilities. Each alternative not only varies in price but also in durability and suitability for specific applications. Assessing the long-term vs. short-term costs associated with these materials can lead to better purchasing decisions.

**Tip:** Always evaluate the working environment of the gasket. High-temperature or high-pressure applications may require more specialized materials, which could potentially raise costs. Balancing these factors can help in making informed choices that suit both budgetary and operational needs.

Additionally, it's beneficial to consider sourcing and availability when analyzing gasket sheet substitutes. Some alternatives may have a longer lead time, which can affect production schedules. Establishing a reliable supplier network can mitigate this risk.

**Tip:** Explore local suppliers for sourcing alternatives. Sometimes, regional materials can offer better cost-effectiveness due to reduced shipping and handling fees, making them a viable option for global buyers.

In the quest for optimal sealing solutions, evaluating gasket sheet alternatives involves understanding critical performance metrics. According to a report by the International Organization for Standards (ISO), materials used in gasket sheets must possess specific performance attributes, such as temperature resistance, compressibility, and chemical compatibility, which can significantly impact their longevity and functionality in various applications. For instance, materials like PTFE and graphite have been shown to withstand temperatures up to 500°F and beyond, making them suitable for high-temperature environments.

Moreover, the hydrophobic properties of gasket sheets play a crucial role in performance. A 2021 study published in the Journal of Materials Science found that gaskets with lower water absorption rates resulted in enhanced sealing performance over time, reducing the frequency of maintenance and replacement. By examining these metrics – including compression set, tensile strength, and chemical resistance – global buyers can make more informed decisions when exploring innovative gasket sheet alternatives that best fit their operational needs.